Shentou provides on site services

such as factory audit and pre shipment

inspections in China

such as factory audit and pre shipment

inspections in China

Shentou Services

Shentou acts as the China Office for an UK Client

The Client:

The Client:

A leading European distributor for vehicle accessories, electric and electronic parts. More than 40 year’s history, with annual revenue of approximately US$50 million.

Procurement in China:

Approx. US$10M annually (serviced by Shentou) About 20 active suppliers

Experience with Shentou:

Since 2006

Services by Shentou:

Shentou as its China Office

° New product development

° Vendor management

° Quality control

° General coordination & support

° Procurement Financing

Special Project (1): The “tidy up” of a wiper-blade supplier:

Special Project (1): The “tidy up” of a wiper-blade supplier:

Early August, 2016Early August, 2016

Client’s VIP customer was scheduled to audit a wiper blade supplier in Jiangxi in Nov. In the view of the client, the supplier needed major “tidy up”.

Mid-August

After the initial supplier audit by Shentou’s SQEs, Shentou proposed an improvement plan and started monitoring the implementation by the supplier.

Sept. – Nov.

Shentou’s SQEs worked on-site at the supplier’s three times, for a total of 10 days, providing detailed and practical advisory, coaching and verification. The improvement areas included documentation & process control, equipment re-location, safety feature installation, lighting re-arrangement, 5S upgrade, etc.

25th Nov.

The customer accompanied by the client audited the supplier and were completely satisfied. Even the client manager who regularly visited the supplier commented: “It’s amazing, cannot believe this is the same factory that I have seen before”.

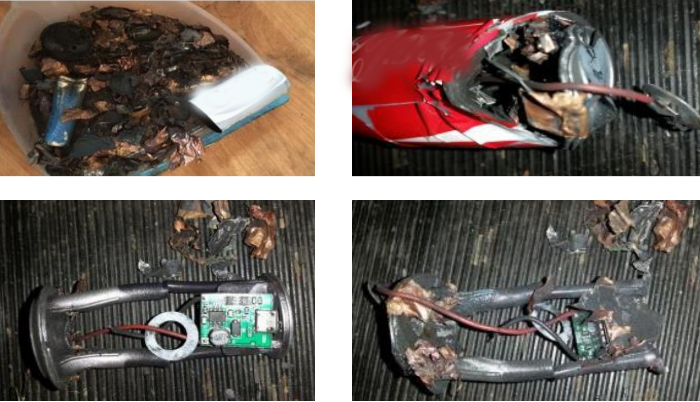

Special Project (2): The “Exploding Portable Power Bank”

Special Project (2): The “Exploding Portable Power Bank”

Mid-August, 2016

End-users of a Coca Cola-branded portable power bank reported 2 cases within a short period of time that the power banks just exploded when first used. The client needed to decide if the whole batch should be called back (total values approx. 500,000 pound). The initial assessment by the supplier: Some issues with the power source PCB redesigned based on the client’s request.

Late August

Shentou inspected the supplier twice, reviewing the complete process control and the production process, and followed up with inspections of the secondary suppliers of the PCB and the power core when we suspected the explosion was due to the power core, instead of the PCB.

Conclusions by Shentou

The secondary supplier of the power core was unqualified and lacked quality assurance capability for its products. The power core should have been rejected by the supplier on inspection. Because of the supplier’s in-competence in their secondary supplier audit and warehouse management, defective power cores were used in the end products and resulted in the explosion.